Medical Systems for Industry

Hauppauge, NY -

Tel (631) 804-

Copyright 2021

Medical packaging equipment and packaging materials for medical device, pharmaceutical and diagnostic test kit packaging

Medical Systems for Industry

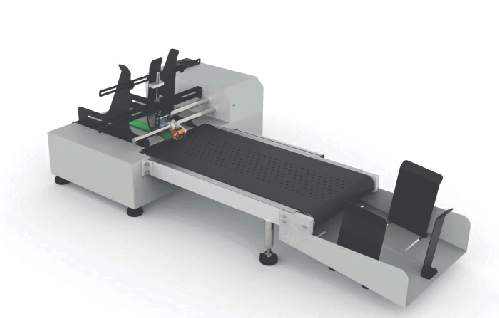

Flat Product Feeding System -

Inspection of bar codes for UDI compliance for medical packaging needs -

Table top flat product feeding system; flat products can be feed from a stack and inspected with vision inspection system

Please contact for equipment details and pricing information

Feeder system, transporter -

The feed system features friction in-

The bar code verifier will make a 100% inspection of each flat product. A Bar Code Verifier will read the Bar Code that was entered and actually do a verification of the attributes (density, type, spacing, width, etc.) and Grade it as an A,B,C, D or F.

A more comprehensive vision inspection system breaks down the Vision Inspection of the desired copy in up to 4 Quadrants so that the customer can isolate up to four sections of the read area for four separate vision inspections.

Net Weight: 140 lbs.

Dimensions: 36” L x 20” W x 22" H

Vacuum Feed Bed: Standard

Electrical Requirements: 110/220 VAC @ 50/60 Cy.

Speed: Adjustable up to 200 ppm

Hopper Feed: Friction Belt

Product Size: 2” x 2” up to 12” x 12” Std.

Product Thickness: 0.004” -

| Medical Systems Home Page |

| Foil Pouch Printing Equipment |

| Pouch Printing Equipment |

| Tyvek Lidding Printing Equipment |

| Hot Stamp Printer |

| Pouch Printing Equipment Semi-Automatic |

| Webstock Printing Equipment |

| Table Top Blister Sealer |

| Blister Heat Sealer |

| Rotary Blister Heat Sealer |

| Thermoform Tray Leak Detection |

| Medical Vacuum Form Fill Seal |

| Modified Atmosphere Blister Packaging |

| Laboratory Thermoformer |

| Package Integrity Testing |

| Semi-Automatic Form Fill Seal |

| Laboratory Thermoformer |

| Thermoformed Tray Leak Detection |

| Custom Poly Bags |

| Heat Seal Foil Bags |

| Desiccants |

| Tyvek Pouches |

| Tyvek Medical Header Bags |

| Tyvek Lidding |

| Tyvek Rollstock |

| Foil laminate rollstock |

| Thermoform Trays |

| Medical Packaging Supplies |

| Micro Fluid Foil Bags |

| Heat Seal Foil Bags for Lyophilization |

| Heat Seal Foil Bags for Diagnostic Test Kits |

| Peelable Foil Pouches |

| Foil Pouches for packaging disposable electrodes |

| Trays for Clincal Trials |

| Thermoform Trays for Catheters |

| Custom Poly Bags |

| Tyvek Pouches |

| Tyvek Rollstock |

| Tyvek Medical Header Bags |

| Tyvek Lidding |

| Thermoform Trays |

| Heat Seal Foil Bags |

| Desiccants |

| Medical Packaging Roll stock |

| Desk Top Automation Robotics |

| Automation assembly machinery |

| IVD Diagnostic Test Kit Assembly Machinery |

| Assembly Automation |

| Diagnostic Tes Kitt Assembly Machinery |

| Robotic Assembly |

| Automation assembly machinery |

| Catheter Tipping Equipment |

| Catheter Packaging Equipment |

| Mini-Winder |

| Custom Tubing Coilers |

| Medi-Winder |

| Hose Coiler |

| Tay-pr - Taping Machine |

| Tubing Coiler |

| Coil Forming Machine |

| IV Line Assembly Machine |

| Tubing Processing Equipment |

| Mini-Winder |

| Medi-Winder |

| Tubing Coiler |

| Hose Coiler |

| Tay-pr - Taping Machine |

| Coil Forming Machine |

| IV Line Assembly Machine |

| Contact Us |